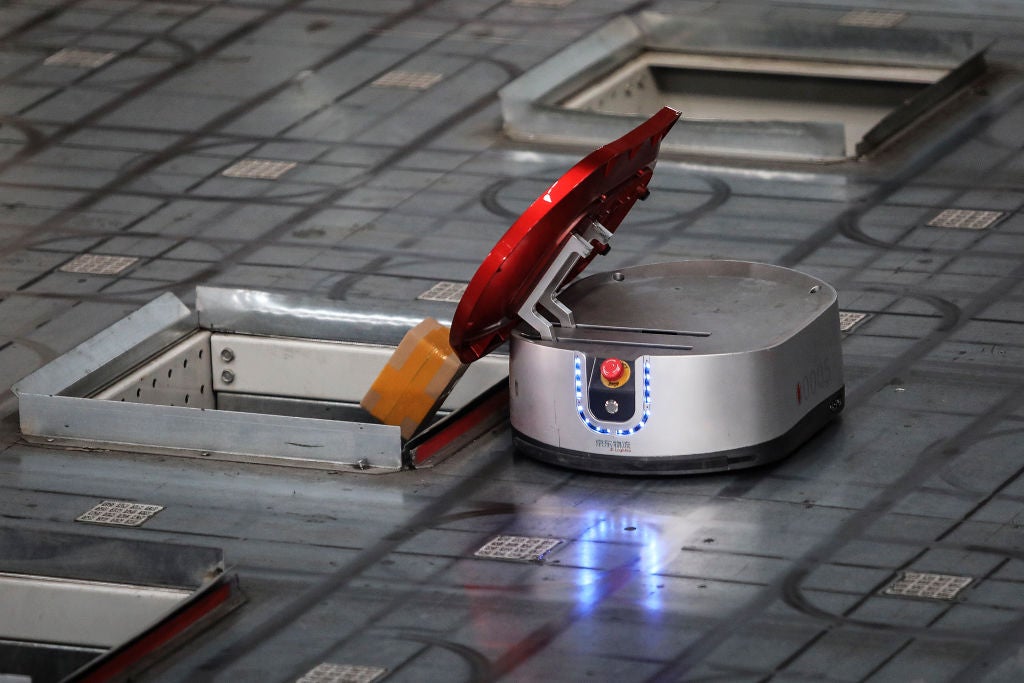

In 2019, robot manufacturer Boston Dynamics announced the launch of Spot, a four-legged robot meant to optimise warehousing activity thanks to its ability to carry up to 14kg and navigate difficult terrain smoothly.

The use of robots and augmented reality (AR) in the warehousing and logistics sector has been gaining momentum since before the Covid-19 pandemic struck. In 2019, projections expected online shoppers to double in the following three years compared with the levels seen in 2014.

Since then, the outbreak of Covid-19 and other disruptive events, not only for the warehousing and logistics sector, but for supply chains more generally, have forced the industry to do some serious soul-searching and at times come up with creative solutions.

The use of AR, robots and AI has gained more traction as a result.

For example, in 2021, Boston Dynamics presented Spot’s more evolved sibling, Stretch, a commercial robot specifically created for warehouses and designed to tackle a number of case-handling tasks, starting with truck and container unloading and later expanding into order building. It can move boxes up to 23kg and work for more than eight hours on a single charge or up to 16 hours with a high-capacity battery option.

What is driving the AR revolution?

Research from Interact Analysis shows that the global warehouse automation market will grow from $29.6bn in 2020 to $69bn in 2025. The drivers behind this growth are plenty.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIncreasing demand for goods, especially during the Covid-19 outbreak, has put more pressure on the pre-existing issue of warehouse space shortage and contributed to making the need for warehouse expansions more urgent.

Warehouse expansions are resource-intensive operations where the use of AR could play a pivotal role. Construction companies, for instance, have started implementing the use of AR glasses to help clients envision the end result before construction begins.

Rising labour costs coupled with labour shortage issues have also been posing supply chain challenges and the role that AR and robots play in improving productivity and accuracy is proving crucial. Warehouse pickers, for instance, are essential to get the right goods to the people who order them in a timely manner.

Recent research shows that pickers spend half their manual picking time walking down warehouse aisles. According to this study, the use of AR is particularly useful for inexperienced pickers, resulting in spending 37% less time completing their orders.

A practical experiment run as part of this study showed that the workers using the AR tool were able to complete the task in an average time of 10.3 minutes, while the workers using paper lists took an average of 16.5 minutes.

“AR and robots will significantly increase productivity and profitability by reducing the need for humans to perform tedious yet necessary tasks, such as restocking shelves,” says Douglas Kent, executive vice-president of strategy and alliances at the Association for Supply Chain Management (ASCM).

“They will also help to ensure safety needs are met, especially in higher-risk roles such as warehousing, mining or truck driving. In warehouses, for example, robots will take over tasks such as lifting and moving heavy objects, minimising the risk of overuse, burn-out and injuries to workers.”

Workforce safety is an area that Boston Dynamics had in mind when designing Stretch. “Stretch can take on the physical labour of warehouse workers who are tasked with moving boxes for eight hours a day or more," says a company spokesperson. "This work is not only physically demanding, but exposes workers to the risk of injury, some of which can be debilitating for life.

“These positions tend to have the most turnover in the warehouse, and we believe that these workers can be used for more valuable, engaging work in the field.”

Until now, AR has been mostly consumed by the public. However, that trend is expected to change in the next decade as more industries start to look at this space.

According to GlobalData thematic research into AR in 2021, consumer AR accounted for 88% of total AR revenue in 2020. However, the enterprise segment is expected to become dominant by 2030, accounting for nearly two-thirds of total revenue.

“Large enterprises across healthcare, logistics, manufacturing and defence are adopting AR for daily operations," says the research paper. "The use of AR headsets is on the rise, mainly for training purposes.

“For example, in April 2021, Microsoft won a contract, potentially worth $22bn over ten years, to supply 120,000 HoloLens headsets to the US Army. Despite this, large-scale enterprise adoption of AR devices will be limited in the short term due to their high cost and relative immaturity.”

Investing in talent

Talent development is another area where AR and robots are seen as valuable tools. Companies have been testing AR solutions in warehouse environments for years with the aim of improving accuracy and efficiency throughout the supply chain.

A 2019 report from Zebra Technologies shows that 93% of survey respondents expected to have adopted wearable computing devices by 2028. The survey also showed outstanding growth in the adoption rate of AR across a variety of warehousing technologies.

Since Stretch launched for commercial sale in 2022, early adopters have included DHL, Performance Team (a Maersk company), and most recently NFI.

For many of them employee training was one of the main drivers. “It is a common misconception that robots will displace human workers," says the ASCM's Kent. "In reality, these technologies will advance the workforce, cultivate a more competitive talent pool and create new job opportunities. Essentially it moves workers into more important and value-added roles.

“Collaborative robots – ‘cobots’ – will only excel with proper human support, thus creating a need for organisations to hire additional talent and reskill their existing workforce.”

GlobalData analyst Emilio Campa adds that while the view that robots will replace human workers is correct, a lot of industries are facing ageing populations, to which robots are one main solution.

“The use of AR and robots might also help attract younger employees as the company might be viewed as more tech positive and innovative,” he says.

On top of that, AR and robots shift labour forces towards being more tech-savvy as employers will need more workers that understand robotics/AR systems, Campa adds.

Potential downsides and risks

The use of advanced technology such as AR and robots still presents some challenges for warehouses. First of all, it is still expensive – Stretch, for instance, comes at a price of $75,000 per model.

While time is likely to fix this – as new technology tends to get cheaper as demand grows – other difficulties might be harder to overcome. Cybersecurity is one of them.

“Increased digitalisation and interconnected devices mean an increased attack surface for hackers and more for companies to defend,” says GlobalData’s Campa.

Usability is also another concern that might stand in the way of warehousing and logistics companies adopting AR and robots, especially as prices remain high.

“It is still early days for these technologies, especially for AR,” argues Campa. “Companies are often wary of introducing a technology that might end up not being needed or even advanced enough to fit the needs of the workforce.”

Boston Dynamics agrees that usability can be an issue and says it has designed its latest robot to adequately meet this challenge.

“The potential downsides of this technology really lie in usability – are they easy to use or can anyone learn how to operate the technology?" says the company spokesperson. "Stretch, for example, is designed for easy deployment and operation and can be installed and ready to work within existing warehouse infrastructure in just a few days.”

The industry knows that making warehousing, logistics and ultimately supply chains more resilient and sustainable in future means taking risks, and comes at a cost. AR and robots seem set to play a key role in the industry’s future development.